Can The Non-stick Nature of the PTFE Conveyor Belt Meet the Cleaning and Hygiene Requirements During Food Processing to Ensure Food Safety in the Food Processing Industry?

In the food processing industry, the non-adhesive nature of PTFE conveyor belts can indeed meet the cleaning and hygiene requirements during food processing to ensure food safety. The following is a detailed analysis of the issue:

Non-adhesive characteristics:

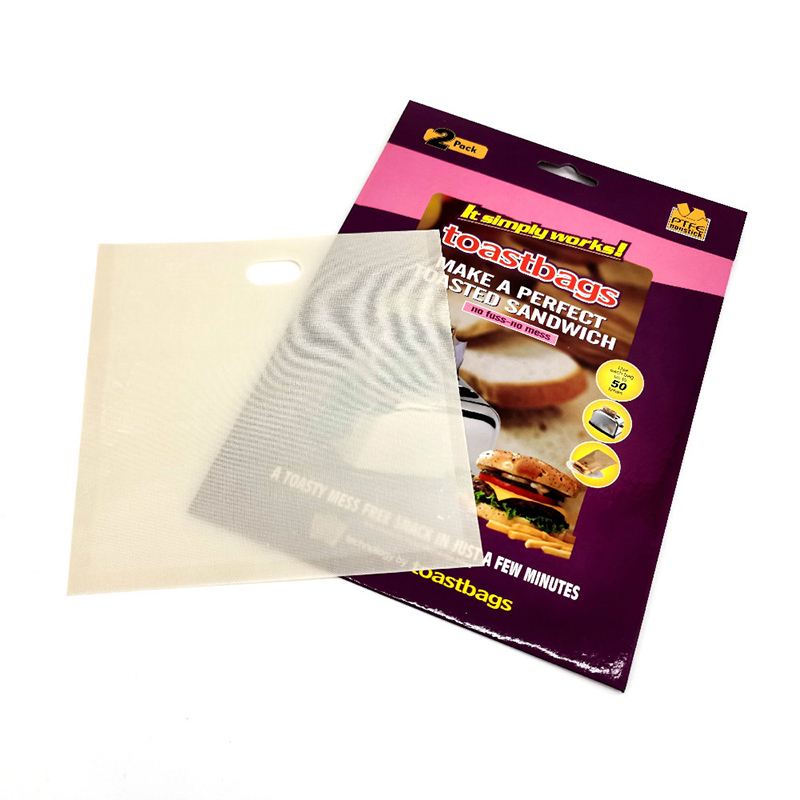

PTFE Conveyor Belt has significant non-adhesive properties, which means that it does not easily adhere to any substance, including food residues, grease, moisture, etc. This feature makes cleaning during food processing easy and efficient.

Easy to clean:

Due to its non-adhesive nature, the PTFE Conveyor Belt can be easily cleaned of various oil stains, stains or other attachments that are attached to its surface. This helps ensure a hygienic food processing environment by reducing the risk of bacterial growth and cross-contamination.

Consistent with food processing hygiene standards:

The food processing industry places high demands on hygiene standards, especially for food contact surfaces. The non-stick nature and ease of cleaning of the PTFE Conveyor Belt make it fully compliant with these standards, ensuring that food is not contaminated during processing.

Extended service life:

Because it is less likely to adhere to substances, the PTFE Conveyor Belt has a relatively long service life. This reduces the frequency of conveyor belt replacement, reduces production costs, and improves production efficiency.

Improve food safety levels:

Overall, the non-adhesive nature of the PTFE Conveyor Belt provides a clean and hygienic production environment for the food processing industry, thereby helping to increase food safety levels. This is important for protecting consumer health, maintaining the company's reputation, and meeting regulatory requirements.

English

English Español

Español русский

русский