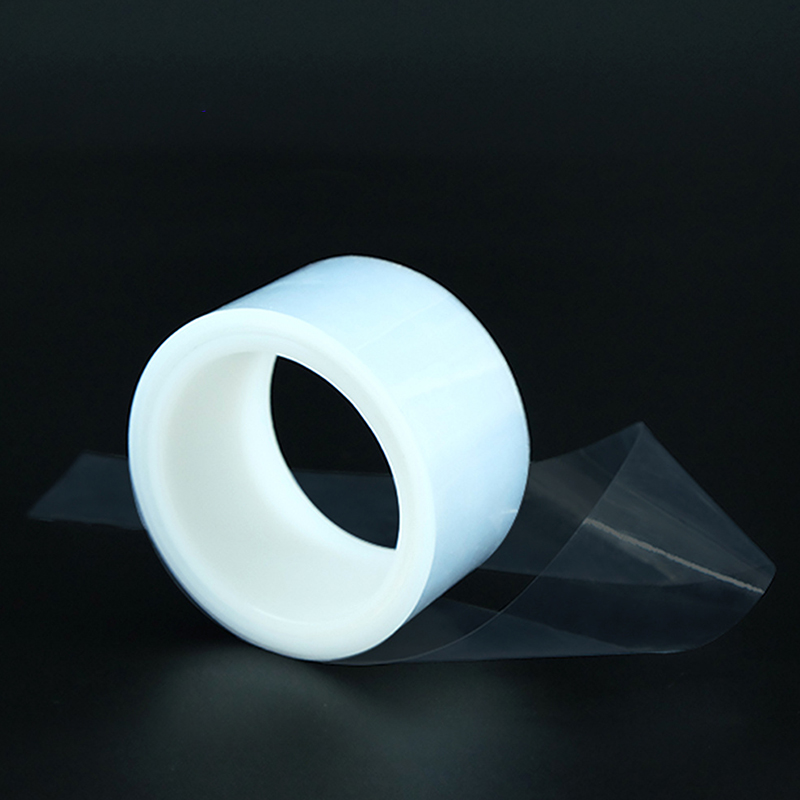

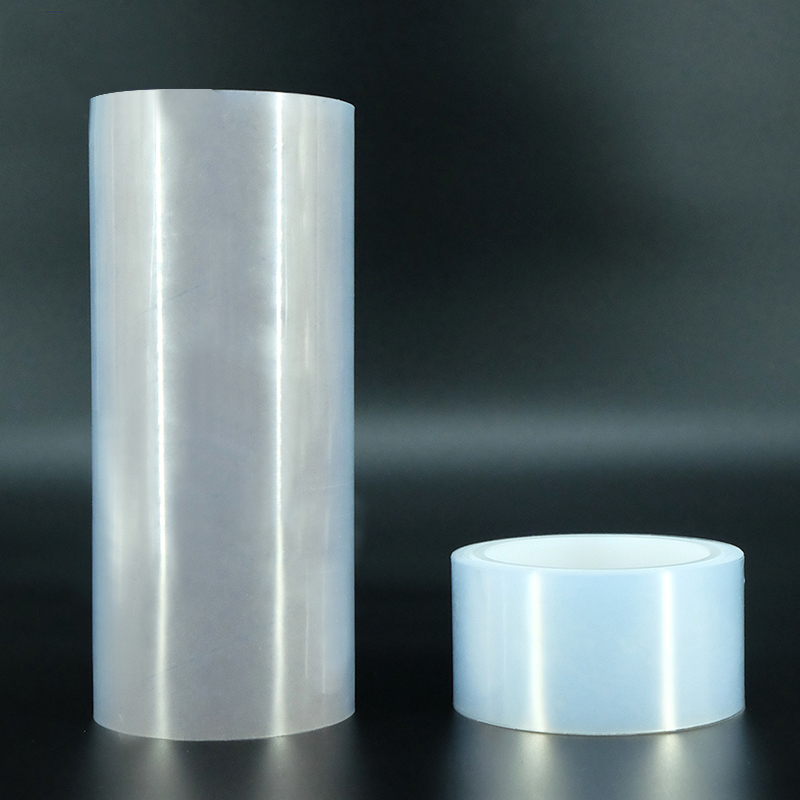

You will need Etched PTFE Film when you bond standard PTFE to another surface such as stainless steel, rubber, and other materials.

Sodium naphthalene treatment strategically disrupts the tightly packed fluorine atoms on the PTFE surface, exhibiting a higher affinity for adhesives and other materials.

PTFE Etched Film Application:

High-Temperature Applications: Etched PTFE film finds particular value in high-temperature adhesive tapes. The synergy between its non-stick properties and strong bonds makes it ideal for demanding environments where traditional adhesives might fail.

PTFE-Metal Composites: Etched PTFE film paves the way for the creation of novel composite materials. For instance, it allows for the secure bonding of copper cladding to PTFE circuit boards, enabling unique functionalities.

Friction Management: The low-friction properties of etched PTFE film are harnessed in applications like mouse pads. The etching process further allows for the secure attachment of the PTFE film to the base material.

Movement and Sliding Mechanisms: Bridge telescopic sliders and gymnasium roof sliders can benefit from the low friction of etched PTFE film while maintaining secure connections with the surrounding structures due to the enhanced bonding capability.

Versatility Across PTFE Products: The etching process can be applied to a diverse range of PTFE products, including molded parts, plates, tubes, rods, films, gaskets, and seals. This broadens the applicability of etched PTFE film across various industries.

English

English Español

Español русский

русский