The self-lubricating miracle of PTFE film: performance from micro to macro

In the vast starry sky of material science, polytetrafluoroethylene (PTFE) film, with its unique self-lubricating properties, is like a bright star, illuminating the way for many industrial and daily applications. When PTFE film rubs against an object, a miracle of the microscopic world quietly takes place - its molecular chains, under the action of friction, weave a continuous and extremely thin lubricating film on the contact surface in an exquisite way. This seemingly insignificant film contains huge energy and profoundly affects the performance and service life of the material.

The microscopic secret of self-lubrication

PTFE, a polymer compound composed of carbon-fluorine bonds, shows amazing self-lubricating ability based on its unique molecular structure. Under the stimulation of friction, the PTFE molecular chains seem to be given life. They move and rearrange on the surface flexibly, and finally form a uniformly covered lubricating film. This film is extremely smooth and can effectively isolate the two friction surfaces, reduce direct contact, and thus reduce the friction coefficient. At the same time, due to the high stability between PTFE molecules, this lubricating film is not easy to be destroyed and can maintain its lubricating effect for a long time.

Efficiency conversion from micro to macro

At the macro level, the self-lubricating properties of PTFE film bring significant benefits. First, it significantly reduces the friction loss and energy consumption of mechanical equipment. In occasions where frequent friction is required, such as textile machinery, food processing equipment, etc., the application of PTFE film can greatly reduce the heat and wear generated by friction, and improve the working efficiency and service life of the equipment. Secondly, the self-lubricating property also means reduced dependence on external lubricants. This not only reduces maintenance costs, but also avoids the environmental pollution problems that lubricants may cause. Finally, the excellent properties of PTFE film such as corrosion resistance and high temperature resistance enable it to maintain a stable lubrication effect in harsh working environments, further broadening its application range.

Wide expansion of application fields

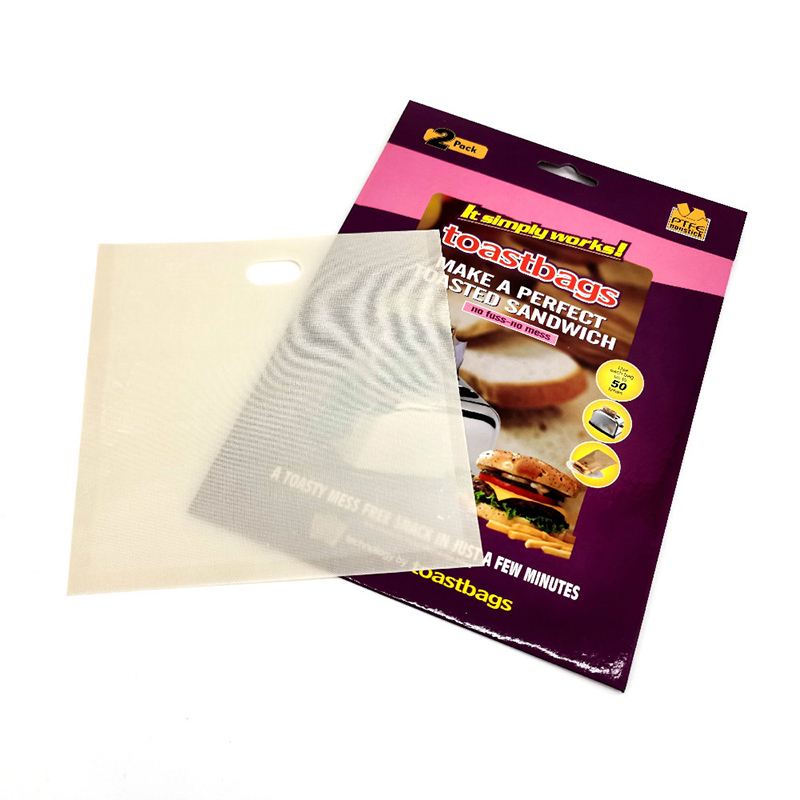

With the advancement of science and technology and the development of industry, the self-lubricating properties of PTFE film have been applied in more and more fields. In the aerospace field, it is used to manufacture high-precision sliding parts to ensure stable performance under extreme conditions; in the field of medical devices, the biocompatibility and self-lubricating properties of PTFE film make it an ideal material for manufacturing artificial blood vessels, catheters and other medical supplies; in daily life, the popularity of non-stick cookware has also allowed people to personally experience the convenience and comfort brought by PTFE film.

The self-lubricating mechanism of PTFE film is a wonderful interpretation in the field of materials science. With its unique molecular structure and chemical properties, it creates a magical lubrication effect at the microscopic level, and is transformed into significant economic and social benefits at the macroscopic level. With the continuous advancement and innovation of science and technology, we have reason to believe that the self-lubricating properties of PTFE film will be applied and developed in more fields, contributing greater strength to the progress of human society.

English

English Español

Español русский

русский