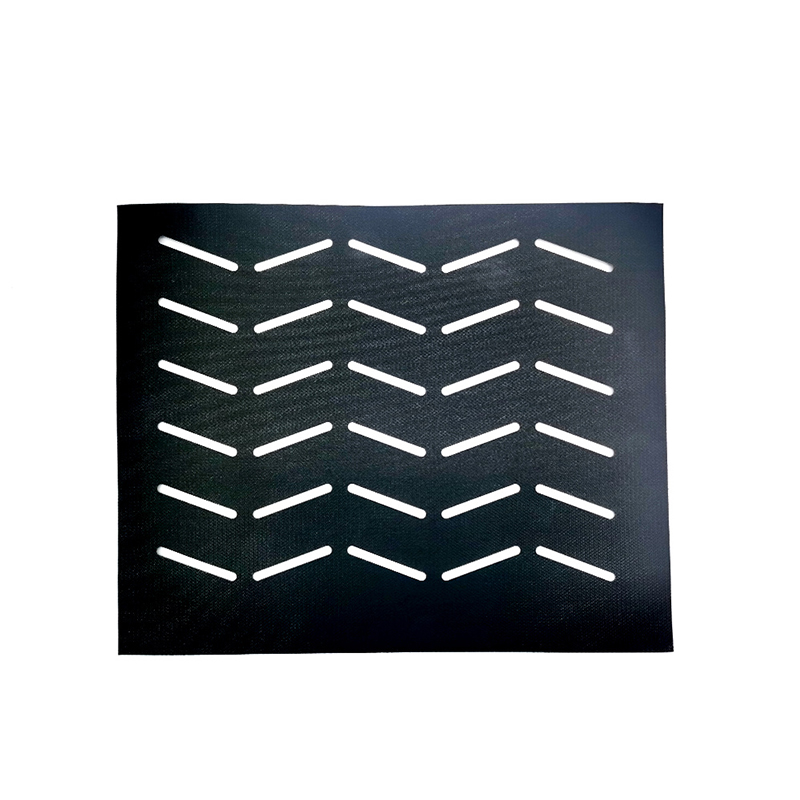

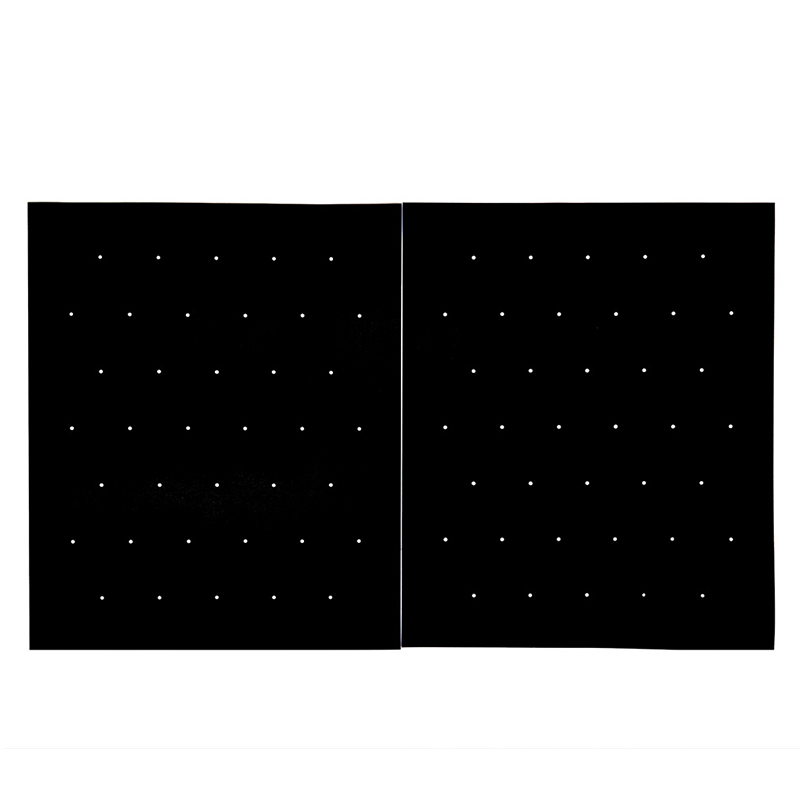

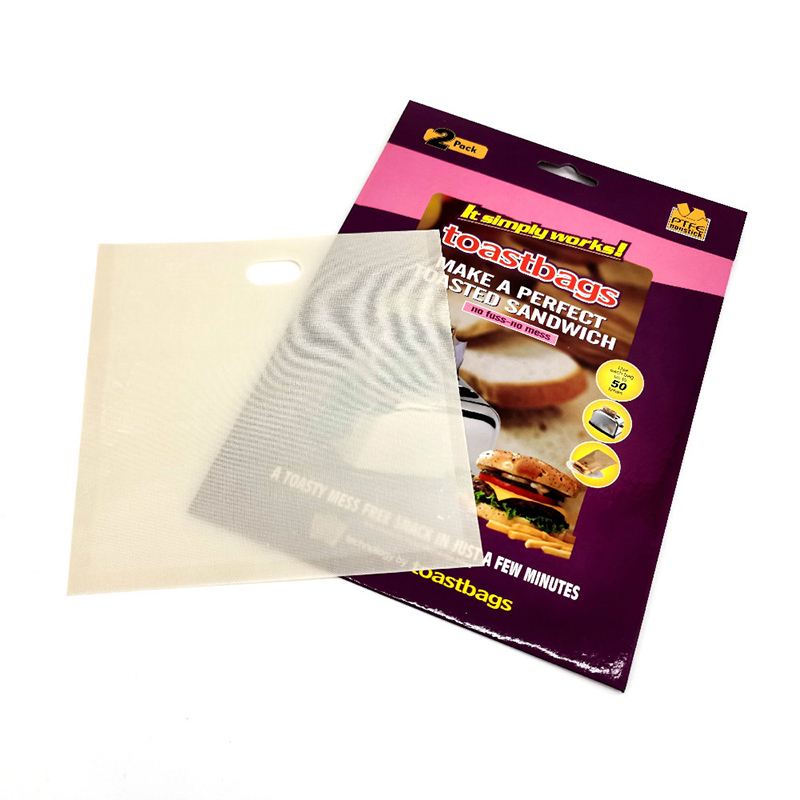

Similar to solid PTFE belts, the PTFE coating on the mesh offers non-stick characteristics. The open mesh construction allows air to flow freely through the belt, which is crucial for tasks like drying, curing, and cooling products. This airflow can significantly improve drying efficiency and prevent heat build-up.

The percentage of open area in the mesh varies depending on the specific belt, typically ranging from 1mm to 6mm. A higher open area allows for more airflow but might have slightly less load-bearing capacity.

PTFE open mesh conveyor belts are used in various industries, including:

Food Processing: Drying fruits, vegetables, and other food products.

Textile Processing: Drying and heat setting of fabrics.

Pharmaceutical Manufacturing: Drying and processing pharmaceutical products.

Electronics Manufacturing: Curing and drying electronic components.

Plastics Industry: Drying and cooling plastic parts.

4x4 open area PTFE mesh belts. Widths reaching up to 5000mm and can be custom-made to any length required especially for Large-scale applications.

Edge reinforcement with film, fiberglass, or Kevlar caters to the specific demands of the working environment, ensuring performance and belt longevity.

English

English Español

Español русский

русский